Delving into the realm of High-efficiency electric motors for industry use, we uncover a world where innovation and productivity collide. From enhancing energy efficiency to boosting performance, these motors are reshaping the industrial landscape in ways never seen before.

As we explore the intricacies of high-efficiency electric motors, a new era of possibilities emerges, offering industries a pathway to unparalleled efficiency and sustainability.

Overview of High-efficiency Electric Motors for Industry Use

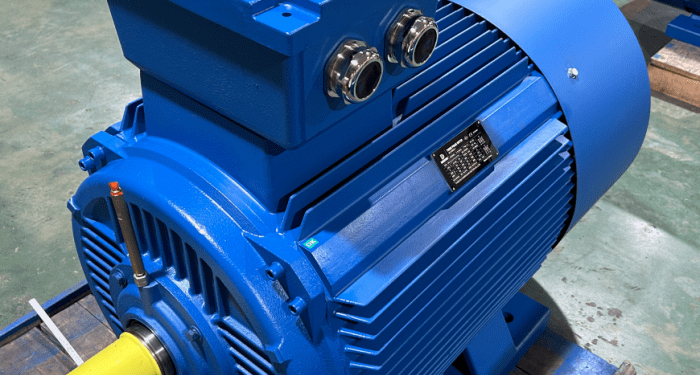

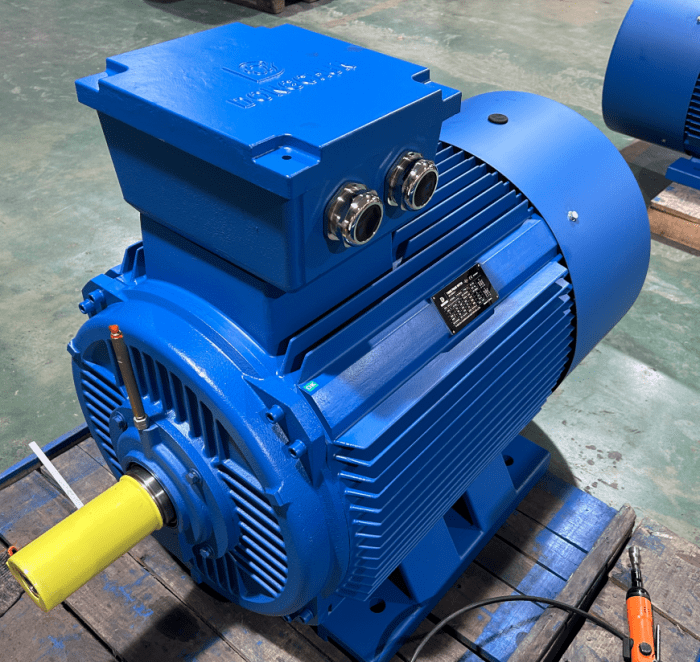

High-efficiency electric motors are specially designed motors that minimize energy loss during operation, making them more environmentally friendly and cost-effective. These motors are crucial for various industries aiming to improve their energy efficiency and sustainability practices.

Importance of High-efficiency Motors in Industries

High-efficiency electric motors play a significant role in reducing energy consumption and operating costs for industries. By utilizing these motors, companies can lower their carbon footprint and comply with environmental regulations while also improving overall productivity.

Industries Benefiting from High-efficiency Electric Motors

- Manufacturing Industry: High-efficiency motors are extensively used in manufacturing plants for operating machinery and equipment, leading to reduced energy consumption and increased production efficiency.

- Transportation Sector: Electric vehicles rely on high-efficiency motors to enhance performance and extend battery life, contributing to the growth of sustainable transportation solutions.

- Renewable Energy Sector: Wind turbines and solar power systems utilize high-efficiency motors to convert renewable energy sources into electricity with minimal energy loss, promoting the adoption of clean energy technologies.

- Commercial Buildings: High-efficiency motors are integrated into HVAC systems, elevators, and other building components to optimize energy usage and create more energy-efficient structures.

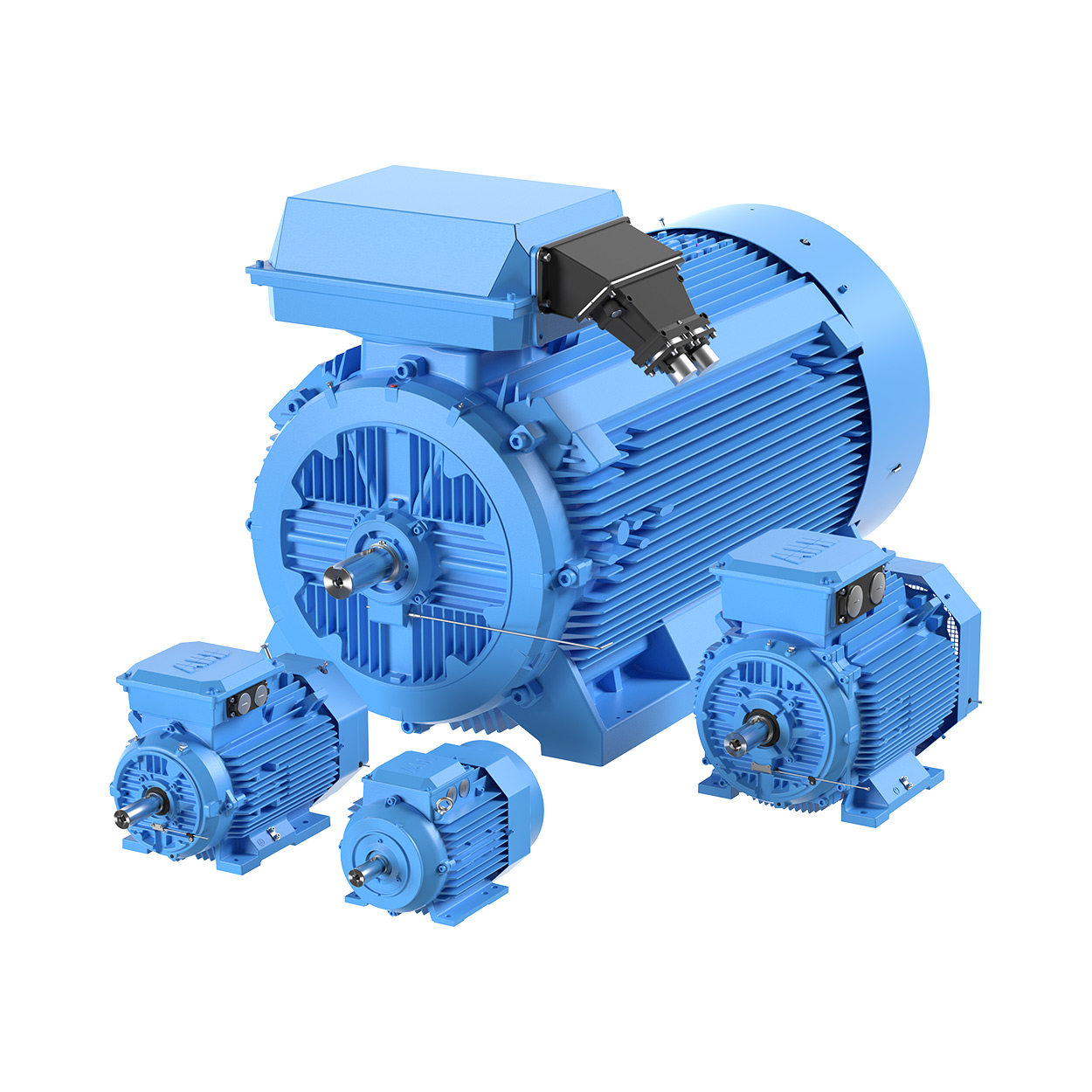

Types of High-efficiency Electric Motors

Electric motors are crucial components in various industrial applications, with different types available to meet specific needs. Let's explore and compare the characteristics and advantages of some common high-efficiency electric motors used in industries.

Synchronous Motors

Synchronous motors operate at a fixed speed determined by the frequency of the power supply. These motors offer high efficiency and power factor, making them suitable for applications where precise speed control is required, such as in pumps, compressors, and fans.

Induction Motors

Induction motors are the most commonly used type of electric motor in industrial settings. They are known for their robustness, reliability, and low maintenance requirements. Induction motors are ideal for applications with variable torque loads, such as conveyors, mixers, and cranes.

Permanent Magnet Motors

Permanent magnet motors use magnets to create the rotor's magnetic field, eliminating the need for rotor windings. These motors are highly efficient and compact, making them suitable for applications where space is limited, such as in robotics, electric vehicles, and aerospace systems.

Brushless DC Motors

Brushless DC motors offer high efficiency, precise speed control, and low maintenance due to the absence of brushes. These motors are commonly used in applications requiring high torque at low speeds, such as in industrial automation, medical devices, and HVAC systems.

Servo Motors

Servo motors are designed for high precision and control in applications that demand accurate positioning and velocity control. These motors are commonly used in robotics, CNC machines, and packaging equipment where precise motion control is critical.

Design Considerations for High-efficiency Electric Motors

Electric motors used in industrial settings require careful consideration of various design factors to ensure optimal efficiency and performance

Role of Materials in Motor Efficiency

Materials play a crucial role in determining the efficiency of electric motors. The use of high-quality materials such as copper in the windings can reduce resistive losses and enhance overall motor efficiency. Additionally, advancements in materials science have led to the development of new alloys and composites that offer improved performance and durability, further contributing to the efficiency of electric motors.

Importance of Cooling Systems

Efficient cooling systems are essential for maintaining the optimal operating temperature of electric motors. Overheating can significantly reduce motor efficiency and lifespan. Modern electric motors utilize advanced cooling techniques such as liquid cooling or forced air cooling to dissipate heat effectively and ensure consistent performance.

By keeping the motor temperature within the recommended range, cooling systems play a critical role in enhancing overall efficiency.

Construction and Design Optimization

The overall construction and design of electric motors also play a significant role in determining their efficiency. Factors such as aerodynamics, electromagnetic optimization, and mechanical design all contribute to reducing losses and improving performance. Through advanced computer simulations and modeling techniques, engineers can optimize the design of electric motors to achieve higher efficiency levels while meeting specific industry requirements.

By focusing on construction and design optimization, manufacturers can create high-efficiency electric motors tailored to industrial applications.

Energy Savings and Cost Benefits of Using High-efficiency Motors

Switching to high-efficiency electric motors can lead to significant energy savings and long-term cost benefits for industries. These motors are designed to operate more efficiently, thereby reducing energy consumption and lowering operational costs over time.

Potential Energy Savings

- High-efficiency motors can achieve energy savings ranging from 20% to 30% compared to standard motors.

- These savings can vary depending on factors such as motor size, load profile, and operating conditions.

- By investing in high-efficiency motors, companies can reduce their energy bills and improve overall energy efficiency.

Long-Term Cost Benefits

- Although high-efficiency motors may have a higher initial cost, the long-term savings in energy consumption can outweigh the upfront investment.

- Reduced energy usage leads to lower operational costs and increased profitability for businesses.

- High-efficiency motors also tend to have longer lifespans and require less maintenance, further contributing to cost savings over time.

Case Studies

Company A upgraded their industrial motors to high-efficiency models and experienced a 25% reduction in energy consumption, resulting in annual savings of $50,000.

Company B invested in high-efficiency motors for their HVAC systems and saw a 30% decrease in energy usage, leading to substantial cost savings over a five-year period.

Company C switched to high-efficiency motors for their manufacturing equipment and not only reduced their carbon footprint but also saved $100,000 in energy expenses within the first year.

Outcome Summary

In conclusion, High-efficiency electric motors for industry use stand as a beacon of progress and innovation, heralding a future where energy efficiency and industrial productivity go hand in hand. Embracing these advanced motors is not just a choice; it's a transformative step towards a more sustainable and efficient industrial landscape.

Frequently Asked Questions

Are high-efficiency electric motors more expensive than traditional motors?

While high-efficiency motors may have a higher upfront cost, the long-term energy savings and operational benefits often outweigh the initial investment.

What industries can benefit the most from using high-efficiency electric motors?

Industries such as manufacturing, HVAC, and transportation can significantly benefit from the energy savings and performance improvements offered by high-efficiency electric motors.

Do high-efficiency electric motors require special maintenance compared to traditional motors?

High-efficiency motors generally require similar maintenance practices as traditional motors, but their design may incorporate features that enhance longevity and efficiency.

Can high-efficiency electric motors be retrofitted into existing industrial systems?

Yes, high-efficiency motors can often be retrofitted into existing systems with proper planning and installation to improve energy efficiency and performance.